Explicit Simulations

Design for fabrication of accelerator components

Explicit simulations are well suited for highly nonlinear problems. By advancing in very small time steps, they capture large deformations, rapid loading, and failure with high accuracy. They are used from industrial forming processes to beam–matter interactions at CERN, where components face sudden and extreme energy deposition.

NON LINEAR SIMULATIONS

From large deformations to material failure

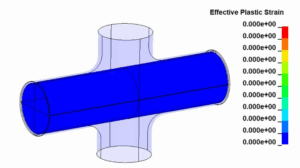

Hydroforming

We use LS-Dyna it to simulate hydroforming of accelerating cavities. High-pressurized water pressure shapes a cylinder by pressing it into a die.

We have also developed a strong expertise in copper and niobium cavity hydroforming.

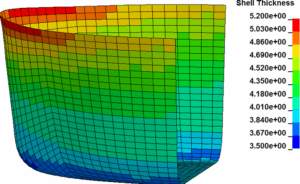

Deep Drawing

Deep drawing is a metal forming process in which a punch forces a sheet of metal into a die cavity, producing deep, hollow components with precise geometries. For the HL-LHC crab cavities at CERN, advanced simulations are essential to optimize the design of production tooling, accurately predict thickness variations during forming, and verify that the niobium parts conform to stringent radio-frequency (RF) performance and dimensional tolerances. These simulations also help identify potential forming defects early, reduce material waste, and ensure consistent quality throughout the manufacturing process, supporting the demanding requirements of accelerator technology.

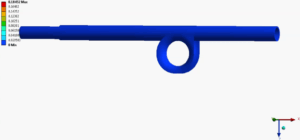

Pipe Bending and Joints

Many upgrades to the cooling lines of CERN accelerators and experiments are ongoing. The design of adequate tools for tube bending / shaping is an important activity, that can be optimized by means of large-deformation simulations. Parameters that can be controlled are geometry, materials, lubricants/friction, etc.

Why use explicit simulations?

Advanced nonlinear simulations allow us to predict behaviour under challenging conditions and provide robust engineering solutions at CERN

FIND OUT MORE

Keen to learn more about our activities?

Find out what the Engineering Unit can do for you.