Use Cases

The FCC-ee

Overview

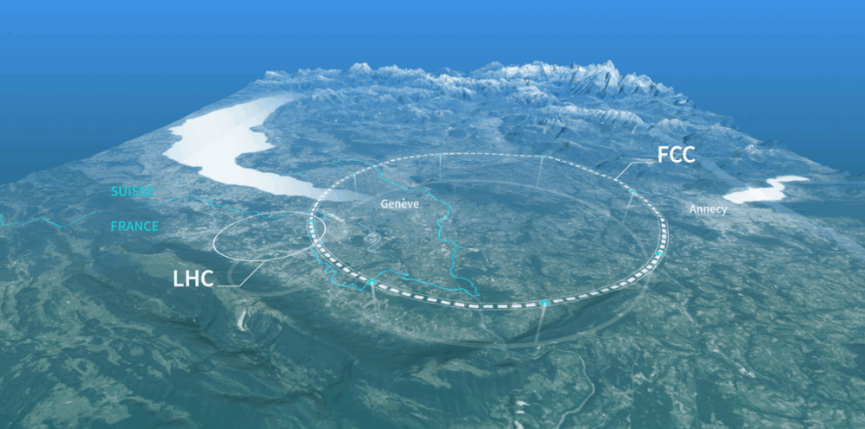

The Future Circular Collider team completed the FCC feasibility study on 31 March 2025 and published its report, which examined the technical and financial viability of the FCC at CERN. The first stage of the FCC will be the construction of an electron-positron collider for precision measurements, with a 15-year research programme from the late 2040s (FCC-ee).

This study requires intensive mechanical engineering analyses across various key topics to ensure optimal performance, safety, and long-term reliability.

Mechanical Engineering for the FCC-ee Study

Building a Mock-up

The current FCC-ee layout considers a circumference of around 90 km. Of this, 85% is taken up by the arcs, which comprise almost 3,000 half cells. The arc half-cell is the most repeated region in the tunnel. For this reason, CERN is building an arc half-cell mock-up, with the goal of testing aspects related to fabrication, integration, assembly, transport, installation, alignment, stability, inspection and maintenance. We are responsible for design, fabrication and installation of this mock-up.

The stability problem

The challenging beam characteristics impose stringent requirements in terms of alignment and nanometric vibration stability. Several sources of vibration can disturb the beam and cause luminosity loss. An experimental campaign and numerical analyses, using Finite Element Analysis (FEA), were conducted in parallel on a simple Short Straight Section (SSS) demonstrator. This multi-stage characterisation aims to understand how the different elements of the SSS affect the overall stability of the system.

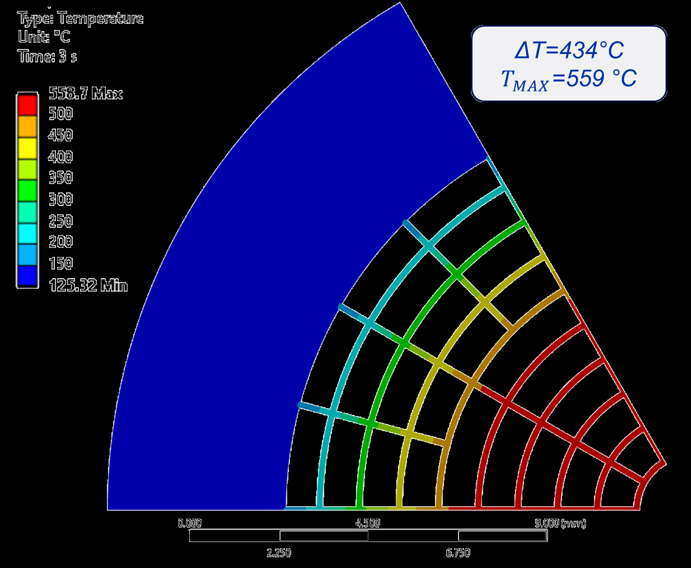

Efficient Power Sources

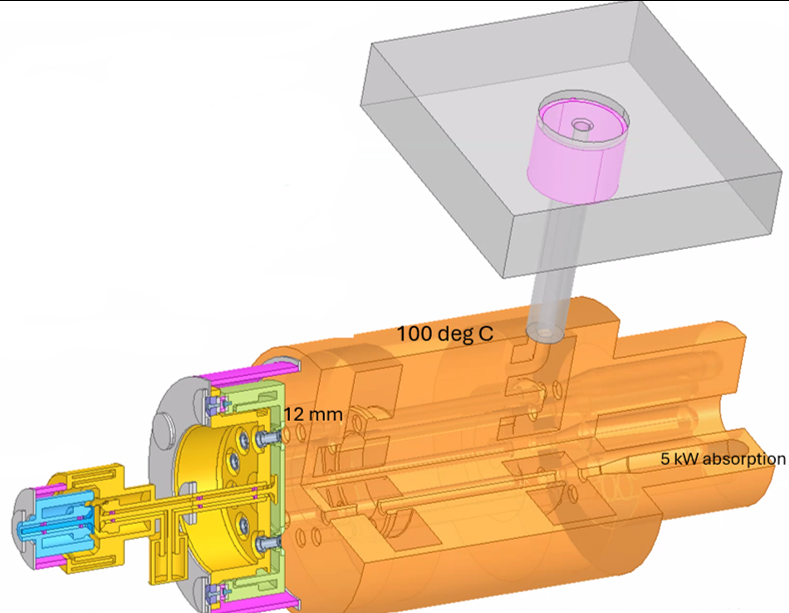

The Tristron project, guided by the RF group, aims at enhancing the efficiency of the systems that power the RF cavities. By improving the power sources efficiency from 60% to over 80%, the project aims at significantly reducing the power consumption of the FCC-ee.

We are in charge of the research & development of materials, simulations and design for this project.

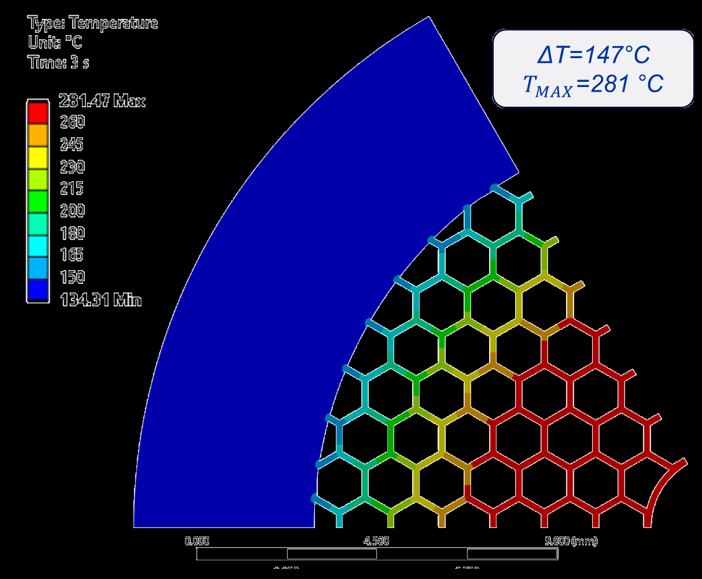

Cost-effective RF Cavities

The manufacturing of Superconducting Radio- Frequency (SRF) cavities is one of the challenging aspects of the project. The feasibility of manufacturing and large-scale production requires strong investigation in the early phases. This is done by combining advanced FEA and experimental tests on mock-ups and prototypes.

FIND OUT MORE

Keen to learn more about our activities?

Find out what the Engineering Unit can do for you.